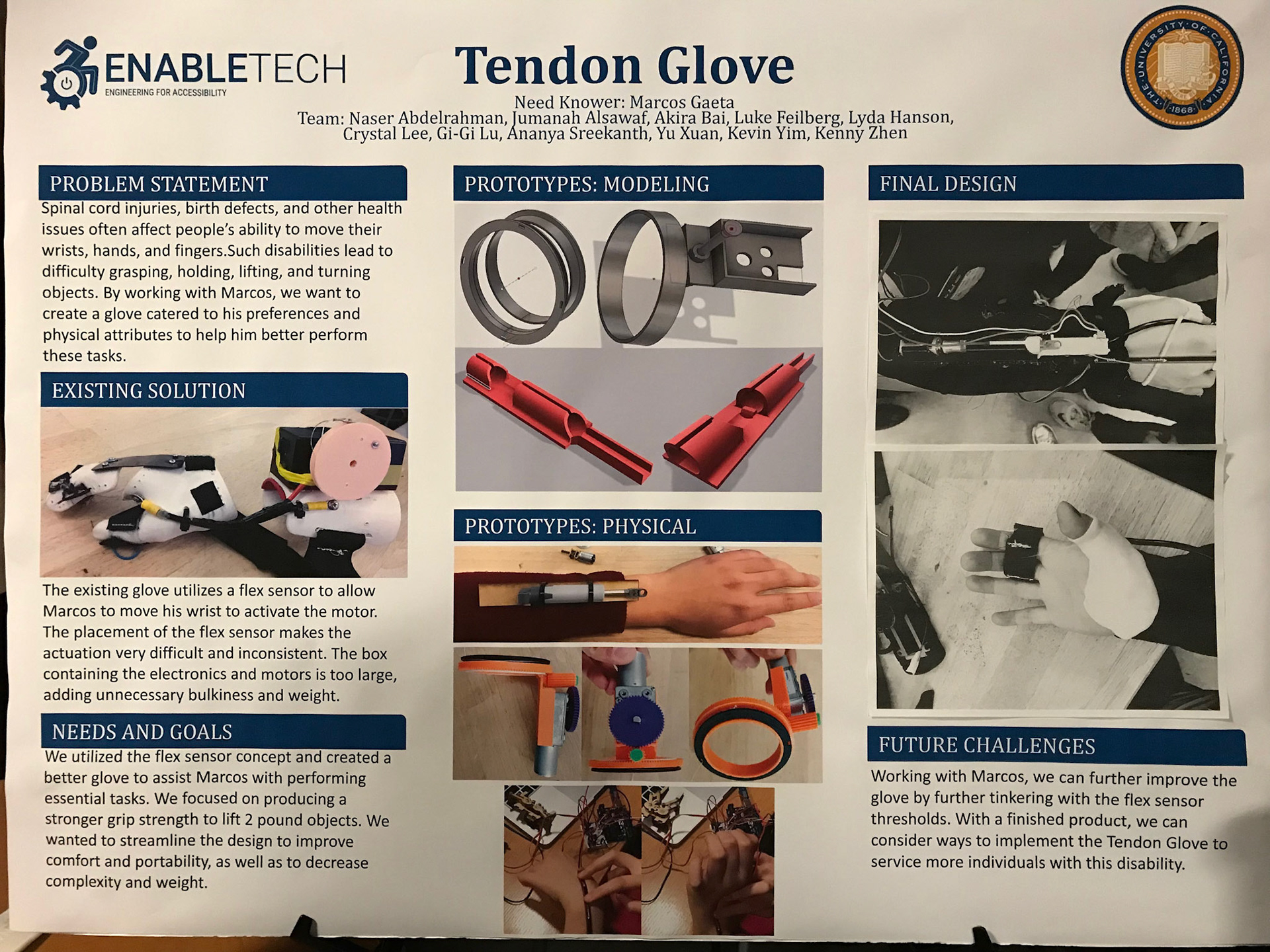

Tendon Glove: A Proof of Concept for a Refined Design

EnableTech • Assistive Technology

EnableTech is a campus organization that gives students hands-on experience in designing assistive technology using user-centered design. Students learn technical skills (3D modeling, 3D printing, laser cutting, electronics and project management) to prototype a novel solution to a disabilities-related challenge.

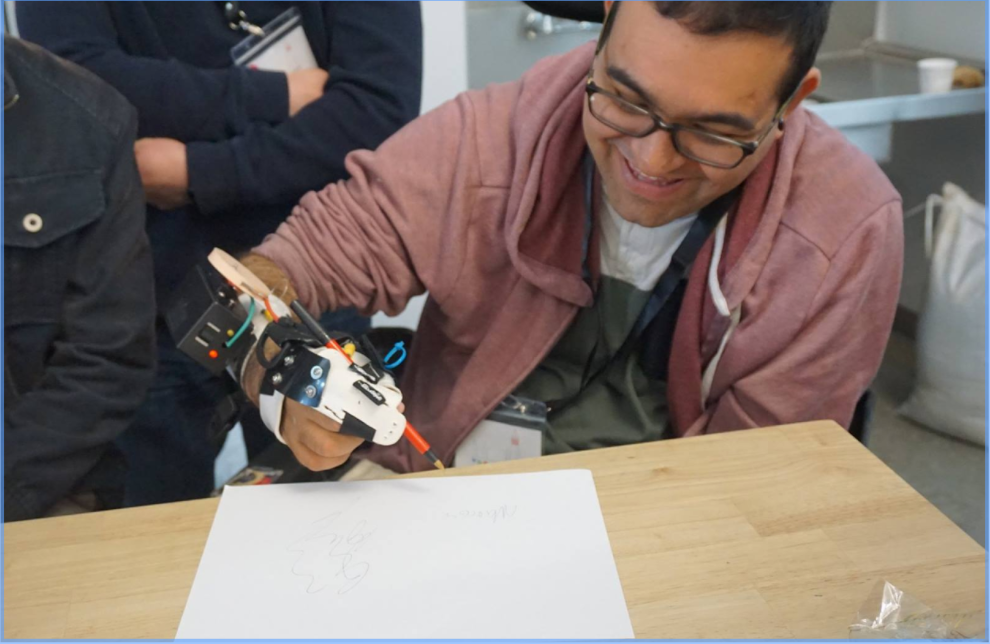

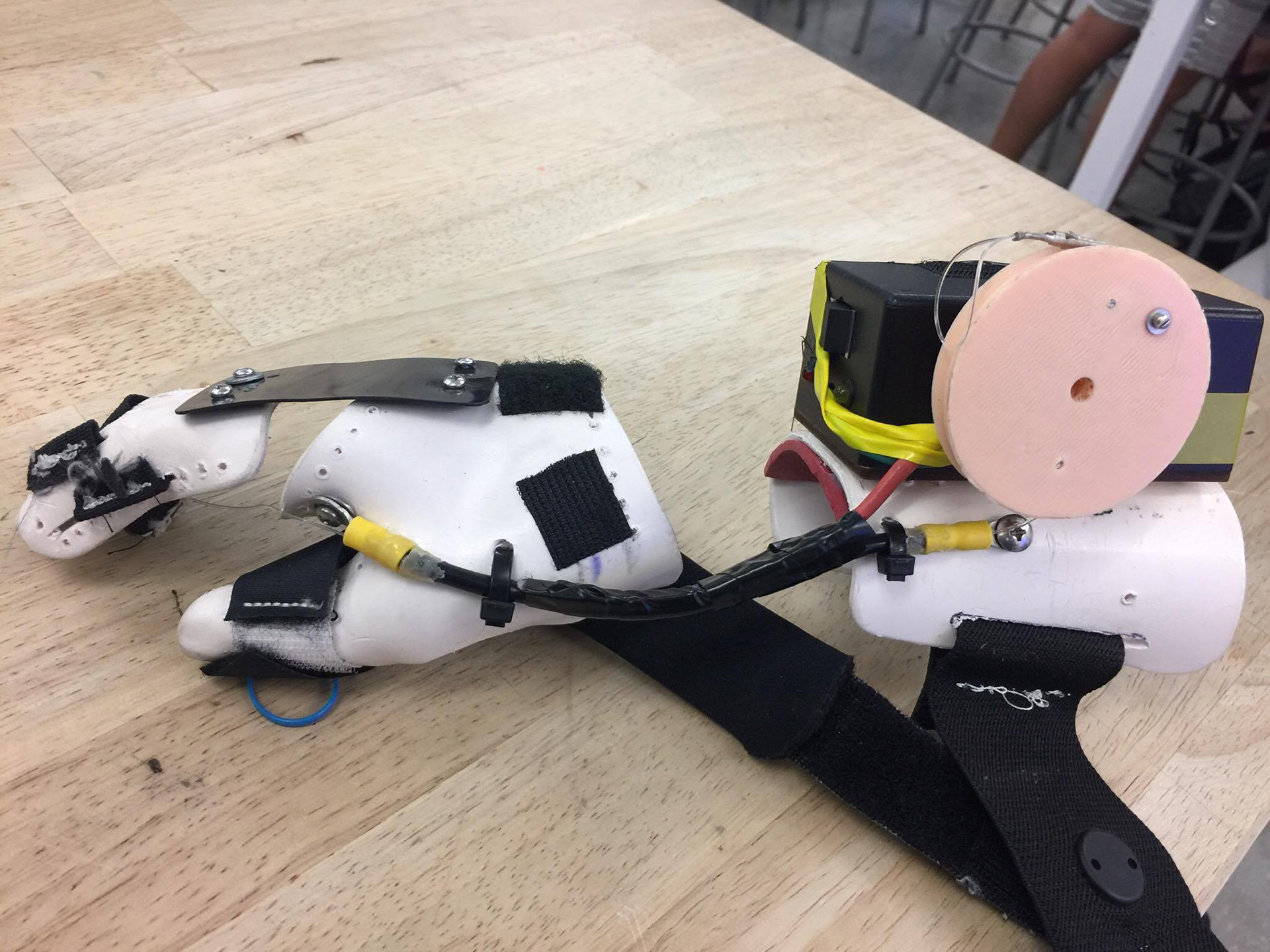

The Tendon Glove team developed an actuated device that assists Marcos, our project partner who has no grip strength due to a spinal cord injury, in performing everyday tasks such as lifting objects and holding utensils.

Working with the original prototype from the 2017 Tikkun Olam Berkeley Makeathon, my team aimed to make improvements in the following areas: comfort, weight, and grip strength.

Marcos testing out the original prototype at the 2017 Tikkun Olam Berkeley Makeathon.

__________________________________________________

New Design

The switch to a linear actuator

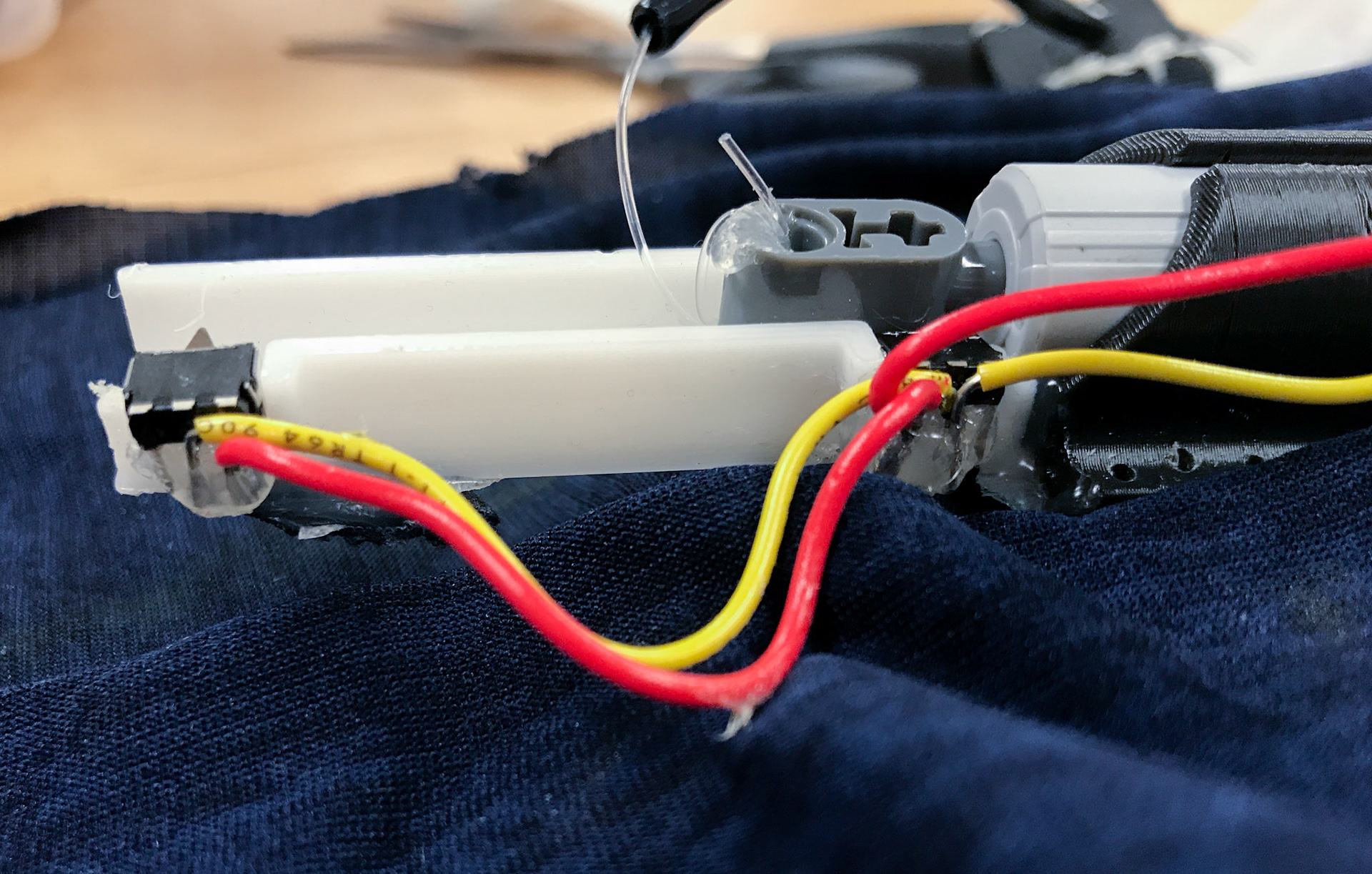

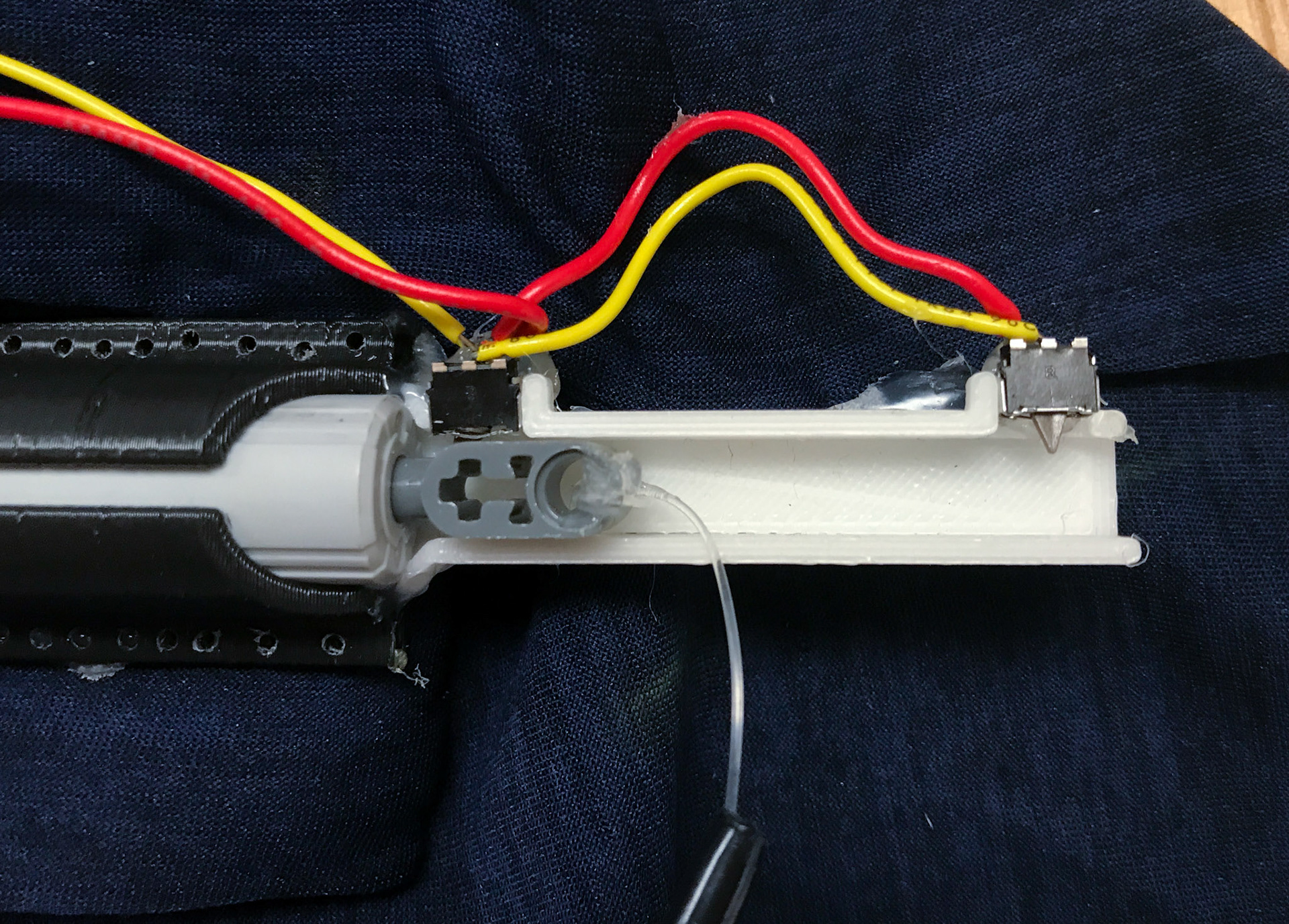

Our design replaces the original gear actuator and servo with a compact linear actuator lego piece and a dc motor along with 3d printed adaptor pieces for a cleaner and lighter design.

The linear actuator and dc motor sit securely in a 3D printed mount, which assembles in three separate components (slide channel, actuator mount, and motor mount). Below is the 3D rendering of the mount. The mount is sewn and glued securely onto the glove to stay in place.

Electronics

The newly integrated microswitches on the ends of the channel through which the linear actuator slides are for directional changes of the actuator. The flex sensor is programmed to activate the actuator when bent at more than 30 degrees, switching the direction of movement with every activation. Using a Feather arduino and Featherwing that are compact, we reduce the size of the electronics component to fit inside the fabric.

Material

To increase comfort, we plan to add fabric around any component of the glove (thermoplastic mold, electronics, flex sensor, etc.) that comes in direct contact with the skin to provide some cushion. We have made the switch from the original cable wire to braided fishing line with a 20lb strength that's thinner and more durable than its predecessor.

__________________________________________________

Prototyping

Through user research and multiple rounds of ideation and iteration, we created various prototypes and presented our functioning device at the EnableTech end-of-the-year showcase. The rough prototype was mainly used as a proof of concept. For future iterations, we plan on further carrying out these modifications and refining our design.